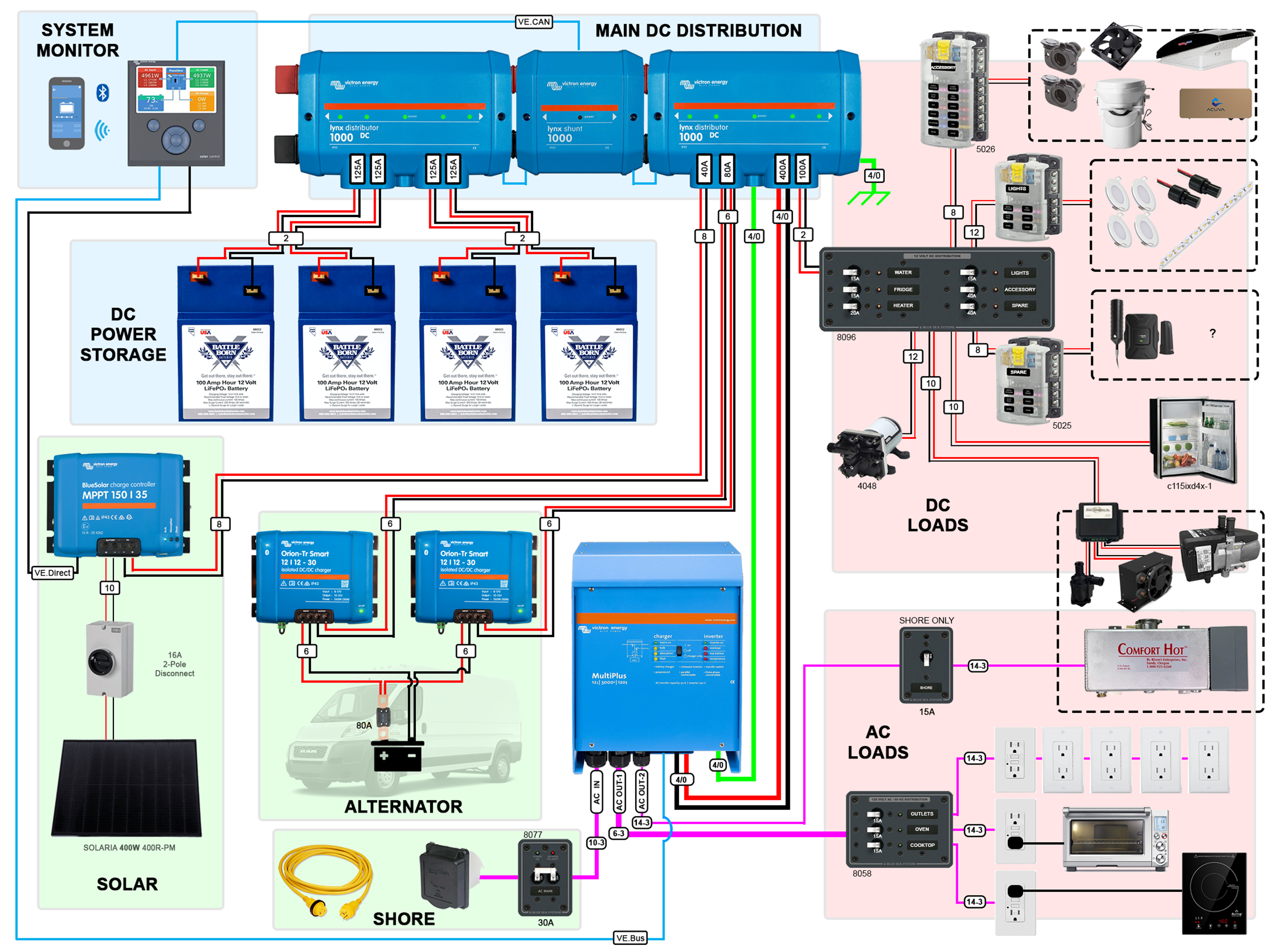

New Van: Electrical System

Disclaimer:

The wire sizes and fuse/breaker sizes notated in this schematic are shown for reference only. It is up to you to determine these parameters based on your specific system. There are a number of different factors that go into wire and circuit protection sizing. Use the Blue Sea Systems Circuit Wizard to help calculate your system requirements.

To make things easier to understand, I’ve broken down each element of the system into sections:

Main DC Distribution

To handle power distribution we used the Victron Lynx system which is a set of fused bus bars with a battery shunt and main fuse. Because the lithium batteries we are using have an internal Battery Management System (BMS), we used the Lynx Shunt VE.Can as our shunt for this setup. Connected to the shunt we have two Lynx Distributors, one for battery connections and one for loads and chargers. Each distributor has 4 fused connection points. Using appropriately sized wire and Mega fuses we connected the battery bank to the left of the shunt and all the loads and chargers to the right side of the shunt.

System Monitoring

The main control center for our electrical system is located in one of the overhead cabinets. Here we have our Color Control GX (CCGX) system monitor as well as the control unit for our Rixens heating system, breakers, shutoff, outlets, and mobile router. Having all the controls in one area inside the cabinet really helps keep things streamlined. The CCGX reads voltage info from the Shunt at the negative connection between the batteries and loads/chargers and communicates with the rest of the components in the system through various communication cables and displays all the system info on the screen. With the CCGX WiFi USB Module, we are also connected to our on-board WiFi so we can see and control our system from anywhere using Victron VRM.

For a more modest system design, you can just use a Lynx Distributor (or Power In) with a BMV-712 shunt.

DC Power Storage

For this build I wired each battery in the bank separately, each on its own circuit. This should provide more balance between the batteries as well as some redundancy in the case of a failure of any one of the batteries themselves. I made all of the cables for the positive and negative of each battery the exact same length. This helps to equalize the rate of charge and discharge of each battery in the bank. For our system, I used 4x 12v 100ah Battle Born LiFePo4 batteries. Each one is wired with 2 AWG battery cable, and runs to the Lynx Distributor on the left side of the Lynx Shunt. Each battery circuit is protected by a 125amp fuse on the Distributor.

Battle Born’s batteries have a max charge rate of 50A per battery and max discharge rate of 100A. So from our 400ah battery bank, we can pull up to around 400A and charge at around 200A. Be sure to take these factors into consideration when sizing your system.

Solar Charging

This is a high quality, super efficient panel that’s a great size for the roof of a van. We almost tried to fit two of these up there but decided that we wanted to add a skylight with a little deck in that space. Turns out that one has worked pretty well for us.

We used an 8020 roof rack kit from DiyVan.com to mount this panel to our roof.

We paired our 400W Solaria panel with the Victron MPPT 150/35 SmartSolar Charge Controller.

It’s important to provide a shut-off from the solar panel(s) to the system. We wired our panel through a 2-pole disconnect switch (positive and negative) before heading to the charge controller.

You will need a VE.Direct cable if you are using a Victron GX Monitoring Device such as the Color Control GX (CCGX) or Cerbo GX. Order a cable long enough to reach your GX device, with some extra slack. I was able to find a VE.Direct cable with a 90degree connector to better fit my installation.

Deployable Solar

For those trips where we know we’ll spend more than one day parked up, we like to bring along our 200 Watt Solar Suitcase from Renogy.

It’s a great way to get some extra charge to our batteries while we’re stationary. Having the ability to angle panels toward the sun makes a big difference, especially in the winter when the sun is low and the days are shorter. This deployable solar kit is super easy to set up, and it’s plug-and-play with its own built-in Voyager charge controller and alligator clips to connect to the battery system.

It folds away and packs into a soft case which fits nicely behind our bed by the back doors.

Alternator Charging

Over the past few years living in a van we find that we tend to move around quite a bit. Getting power from the vans alternator has been instrumental in keeping a full charge. The Victron Orion Tr-Smart has become the standard when it comes to DC-DC charging in a vehicle. The 12/12-30 model has a charge capacity of around 30A at 12V (360W). I decided to run two of these units in parallel to produce 60A of charge current when we drive. The Victron Orion Tr-Smart runs on a smart engine detect system that turns the charger on and off based on the voltage of the starter battery. To get a more accurate voltage and charge efficiency I used the isolated (vs non-isolated) chargers which have terminals for the positive and negative of each side of the charger. Here too I was sure to make the cables for each circuit the exact same length.

To tap into the power of our Promaster, I connected the positive wires to the fuse holder/bus bar on top of the starter battery using two square head bolts at the open terminal. The negatives went to the negative clamp terminal on the battery. Because I used 6 AWG wire for each Orion circuit which would run around 30 amps, I was able to double up both circuits on one terminal using 80amp fuse which is rated low enough to protect each wire individually and high enough to allow the total 60amps coming in from both Orion chargers without blowing. I connected both the Orion chargers to the Lynx Distributor on the same terminal as well with another 80A fuse. This took a little bending of the lugs to get everything all in there.

Shore Power

We installed a 30A service plug through our rear bumper to connect to shore power. Although we don’t typically stay in campsites with hookups, it’s a great feature to have if ever needed. Long, cloudy and stationary days can add up quickly and really deplete your energy. Before reaching our Victron Multiplus Inverter/Charger, the shore circuit runs through a 30A AC Main breaker for overcurrent and reverse polarity protection. With the Victron Multiplus, we can throttle the AC current input to whatever we’re getting from the pedestal/receptacle. This means we can plug directly into a 30A power pedestal at a campground or throttle down the current input and plug in to a standard household 15A receptacle using a 15/30A adapter.

AC Loads

All of our AC loads are powered through our Victron Multiplus. While plugged into external AC power, the Multiplus with its PowerAssist feature can deliver over 50A of current. Although we will probably never use all that, I wanted to set it up to handle that capacity. From the AC-Out-1 connection on the Multiplus I ran 6awg triplex wire to feed a 3 position circuit breaker subpanel. On that breaker panel we have 3x 15A circuits: one dedicated to our toaster oven, one for our induction cooktop and one that runs all of the other outlets in the van. Each circuit is wired to a GFI receptacle with 14awg triplex wire. Additional outlets were wired in from there. On the Multiplus there are two AC-Outs with the second being energized solely by shore power. This was a perfect place to wire up the electrical heating element of our heating system. I put that on a 15A breaker panel of its own.

DC Loads

All of the 12VDC loads in this system first come off the Lynx distributor through 2awg wire and a 100A fuse. That circuit feeds a 6 position 12vdc breaker panel. From there I wired up a few of our appliances directly: WATER PRESSURE (15A), REFRIGERATOR (15A), HEATER (20A)

Then with the remaining openings on the panel, I wired up three subpanels using fuse blocks that would each have their own branch circuits.

I wired in a 12-circuit fuse block for an ‘ACCESSORY’ subpanel using 8awg wire and a 40A breaker, a 6-circuit fuse block for a ‘LIGHTS’ subpanel using 12awg wire and a 15A breaker, and another 6-circuit fuse block to use as a ‘SPARE’ subpanel with 8awg wire and a 40A breaker. I wired the ’SPARE’ subpanel down below the bed so that anything that needed to be wired in at a later date would not need to snake up behind the wall to the control center in the overhead cabinet. Having a main breaker panel really helps you organize and control dc loads.